Esta web utiliza cookies para que podamos ofrecerte la mejor experiencia de usuario posible. La información de las cookies se almacena en tu navegador y realiza funciones tales como reconocerte cuando vuelves a nuestra web o ayudar a nuestro equipo a comprender qué secciones de la web encuentras más interesantes y útiles.

Centro Integrado de Formación Profesional San Gabriel - Escuela de Electricidad, Electrónica y Robótica

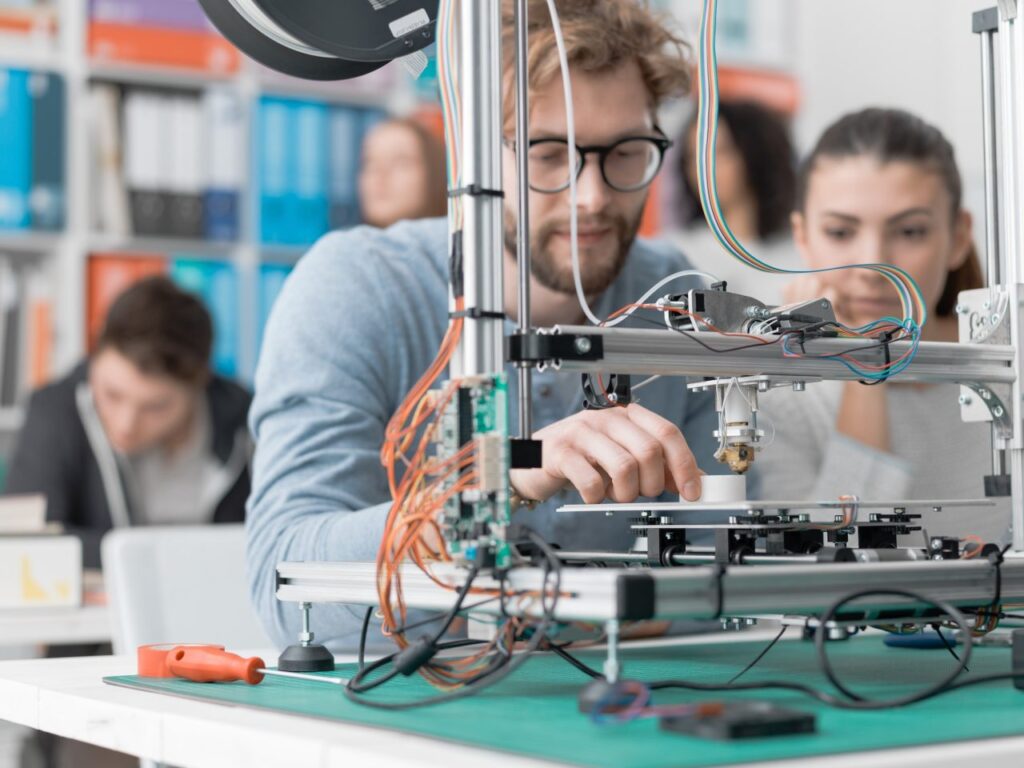

Escuela de Electricidad, Electrónica y Robótica San Gabriel

The importance of the manufacturing sector in the countries' economy has been highlighted in the current crisis. All experts advocate strengthening a key sector that society needs as an engine of its economy and that in recent years has been under great pressure from countries with low labor costs.

The consequences are evident and certainly traumatic; relocation of many companies and what is worse, the disappearance of an important part of the industrial fabric. In this difficult environment, industrial companies face the challenge of searching for and implementing new productive and organizational technologies that allow them to face the future with a guarantee of success. Only a drastic increase in productivity that affects costs and quality will save the manufacturing sector and its jobs.

Innovation through the implementation of new technologies, the continuous improvement of processes through lean manufacturing tools and collaboration with suppliers constitute the three most consolidated alternatives. Its application and potential must be taken into consideration by any company that intends to survive and have a future in the complex economic environment we live in.

Within new technologies, automation and more specifically industrial robotics constitutes a strategy to improve competitiveness that has proven to be able to avoid relocation phenomena. In the US there are hundreds of examples of manufacturers that have avoided relocation by reducing the robot-operator relationship and increasing processes with automated machines. If the ratio in the US is 1 to 240, companies with greater robotization and high profits are 1 to 6. In specific sectors such as machine tool manufacturing, the installation of robots is being intensively promoted due to the increase in productivity that they can provide.

Robotization in itself has two clear initial objectives; reduce manufacturing costs and increase productivity. The additional benefits related to flexibility, security and quality leave no doubt about the profitability of its implementation. Robotics can make tasks simpler that until recently were repetitive, tiring, tedious, dangerous, difficult, precision or developed entirely by hand. The continuous lowering of the cost of acquiring an experienced industrial robot in recent years will cause the manufacturing environment to change drastically in the not too distant future compared to what we know. Plant operators will be technically trained workers with skills in new technologies who will manage automated cells. Its mission will focus on carrying out various levels of inspection, ensuring the flow of materials between different areas.

Contact information

- Tel.: 947 54 50 06 Fax: 947 54 51 61 info@colegiosangabriel.es

Documentation of interest

Obviously not all processes and products can be robotized. This possibility must be addressed through an internal exercise of identification and prioritization of automation based on common sense, technical knowledge and a clear implementation methodology.

When implementing solutions, multiple factors must be taken into account; Firstly, aspects such as the type of product to be manufactured, the production process, safety levels, product quality and the location of the installation. The sector and the requirements of the end customer are also important. The levels of precision, demand, cleanliness and quality required in industries as different as metallurgical, metal-mechanical, food or pharmaceutical are not the same. And finally, it is also very important to be clear about the final production cycle time.

De nada sirve fabricar o automatizar algo de forma correcta si el tiempo que se tarda no cumple con la premisa de ahorrar trabajo, tiempo y dinero. Los estudios realizados en los últimos años muestran que la implantación de robots tiene un amplio despliegue en España a nivel de gran empresa gracias al liderazgo de su industria del automóvil. Sin embargo, su grado de implantación en la PyME es muy diverso y todavía queda mucho por hacer. El campo de actuación urgente en Castilla y León y, concretamente en la Ribera del Duero, justifica la implantación y solicitud de acceso a concierto para este tipo de enseñanzas estratégicas. Las grandes empresas: GSK, Michelin y Calidad Pascual, así como las PYMES, precisan urgentemente de este tipo de talento humano “local”.

It is advisable to strategically anticipate the location of this type of studies in the Ribera del Duero and urgently, thus avoiding the current problems of searching for and retaining talent that large companies and SMEs in the region have already suffered for eight years.

Desde esta concepción, desde el curso escolar 2022/2023 se iniciarán una serie de ofertas educativos oficiales de Grado Superior y de Certificado de Profesionalidad. Iniciamos con el Ciclo Formativo de Grado Superior «Técnico Superior en Automatización y Robótica Industrial».

Desde el curso 2025/2026 el Centro Integrado de Formación Profesional San Gabriel oferta (de forma concertada) el Ciclo Formativo de Grado Superior en Electromedicina Clínica

Sowing the future together!

Discover how at Colegio San Gabriel, we are forging the future through learning and collaboration.